A type newly developed high power small wind turbine

●Low starting wind speed and high utilization rate of wind energy; Small size, light weight, beautiful appearance, low vibration operation. The rotary body can choose the connection type of hoop or flange, which is convenient for various installation requirements.

●The appearance and shape of wind turbine blades are designed with independent intellectual property rights of the company, including classic models, delta wings, flat models, etc., all of which adopt the new technology through precision injection molding, and are equipped with optimized aerodynamic shape design and structure design, with high utilization coefficient of wind energy.

●Most of the built-in copper/aluminum sleeves in the wind turbine blades will not damage the nylon fiber when the bolts are tightened, and the blades are not easy to be deformed or broken. The blade and hub adopt the design of tight concave-convex groove to match more precision, and the wind wheel rotates more smoothly.

●The shell is made of die-cast aluminum alloy, with customized bearing rotation, stronger typhoon resistance, safe and reliable operation.

●The blade and hub are all fastened with stainless steel locknut design, which enhances the anti-corrosion performance and ensures that they are not loose to ensure the normal operation of the fan.

●The generator uses patented permanent magnet rotor AC generator with special stator design, which can effectively reduce the generator resistance torque and thus reduce the starting wind speed; At the same time, the wind turbine and the generator have good matching characteristics, to ensure the reliability of the unit operation.

●Adopt the intelligent tracking technology of wind power generation efficiency, effectively adjust the current and voltage, and the generation conversion rate is high.

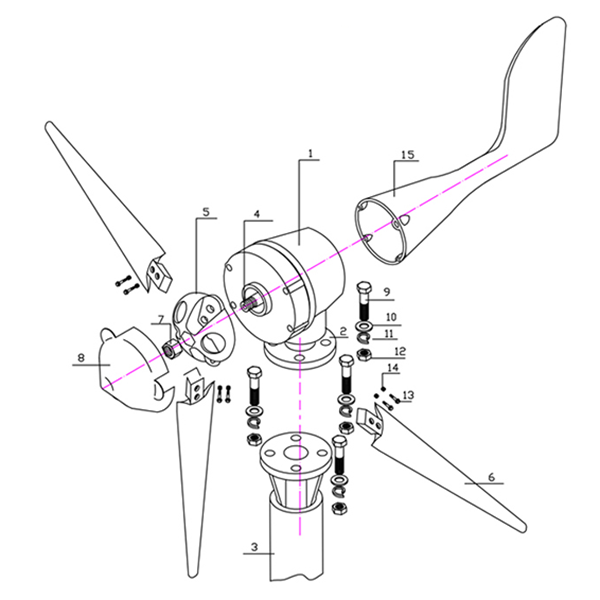

Wind turbine breakdown diagram

1、wind turbines body

2、flange seat

3、steel pipe support

4、wind turbine shaft

5、wind wheel hub

6、wind turbines piece

7、resistance of pine nut

8、fairing

9、bolt

10、flat washer

11、elastic washer

12、nut

13、stainless steel screw

14、resistance of pine nuts

15、stern rudder hull

| Model | WT-A-100W | WT-A-200W | WT-A-300W | WT-A-400W |

| Rated power | 100W | 200W | 300W | 400W |

| Maximum power | 150W | 250W | 350W | 450W |

| Rated voltage | 12V/24V | 12V/24V | 12V/24V | 24V |

| Start-up wind speed | 2.0m/s | 2.0m/s | 2.0m/s | 2.0m/s |

| Rated wind speed | 13m/s | 13m/s | 13m/s | 13m/s |

| Survival wind speed | 35m/s | 35m/s | 35m/s | 35m/s |

| Number of blades | 3/5 pieces | |||

| Blade material | nylon fiber | |||

| Body material | aluminium alloy | |||

| Generator | three phase AC permanent magnet generator/maglev generator | |||

| Control system | electromagnetic brake | |||

| Yaw mode | automatic windward angle | |||

| Lubrication mode | self lubrication | |||

| Tower form | guyed tower/independent tower | |||

| Working temperature | -40°C-80°C | |||

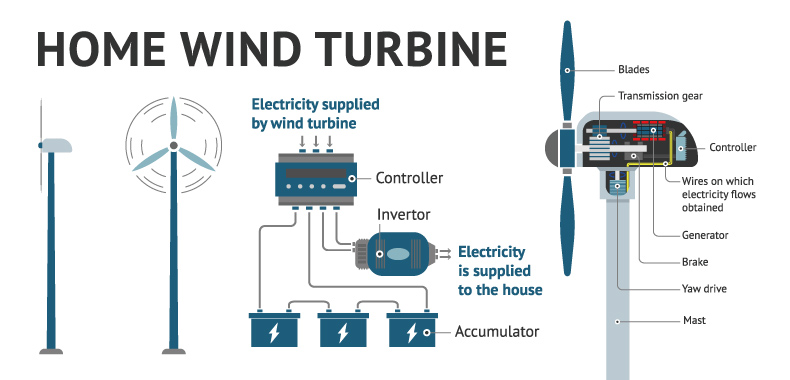

The principle of wind power generation is to use the wind to drive the rotation of the windmill blades, and then through the speed machine to increase the rotation speed, to promote the generator to generate electricity.

Wind power system is very efficient, but it is not only composed of a generator head, but a small system with a certain amount of technology: wind generator + charger + inverter. Wind turbine by the nose, rotating body, tail, blade composition. Each part is important. The functions of each part are: the blade is used to receive the wind and convert it into electricity through the nose; The tail keeps the blades facing the direction of the incoming wind to obtain maximum wind power; The rotating body can make the nose rotate flexibly to realize the function of adjusting the direction of the tail. The rotor of the nose is a permanent magnet, and the stator windings cut the magnetic force lines to generate electric energy.

Because of the unstable air volume of wind turbine, its output is 13 ~ 25V alternating current, which must be rectified by the charger, and then charged to the storage battery, so that the electric energy generated by wind turbine into chemical energy. Then with a protective circuit of the inverter power supply, the chemical energy in the battery into 220V AC mains, in order to ensure stable use.

Household power generation

Street lighting

Agricultural electricity consumption

Offshore wind power

Mountain area power supply

Landscape of Tourism